What's new in NX

Innovations in Siemens NX in December 2024

With NX 2412, you will encounter new capabilities as well as updated enhancements. Here are some of the major new enhancements in the latest release of NX CAM, AM and Design.

NX X for Manufacturing

NX X Manufacturing, the cloud version of NX Manufacturing, was recently launched, delivering flexibility, security, and scalability to CAD/CAM software.

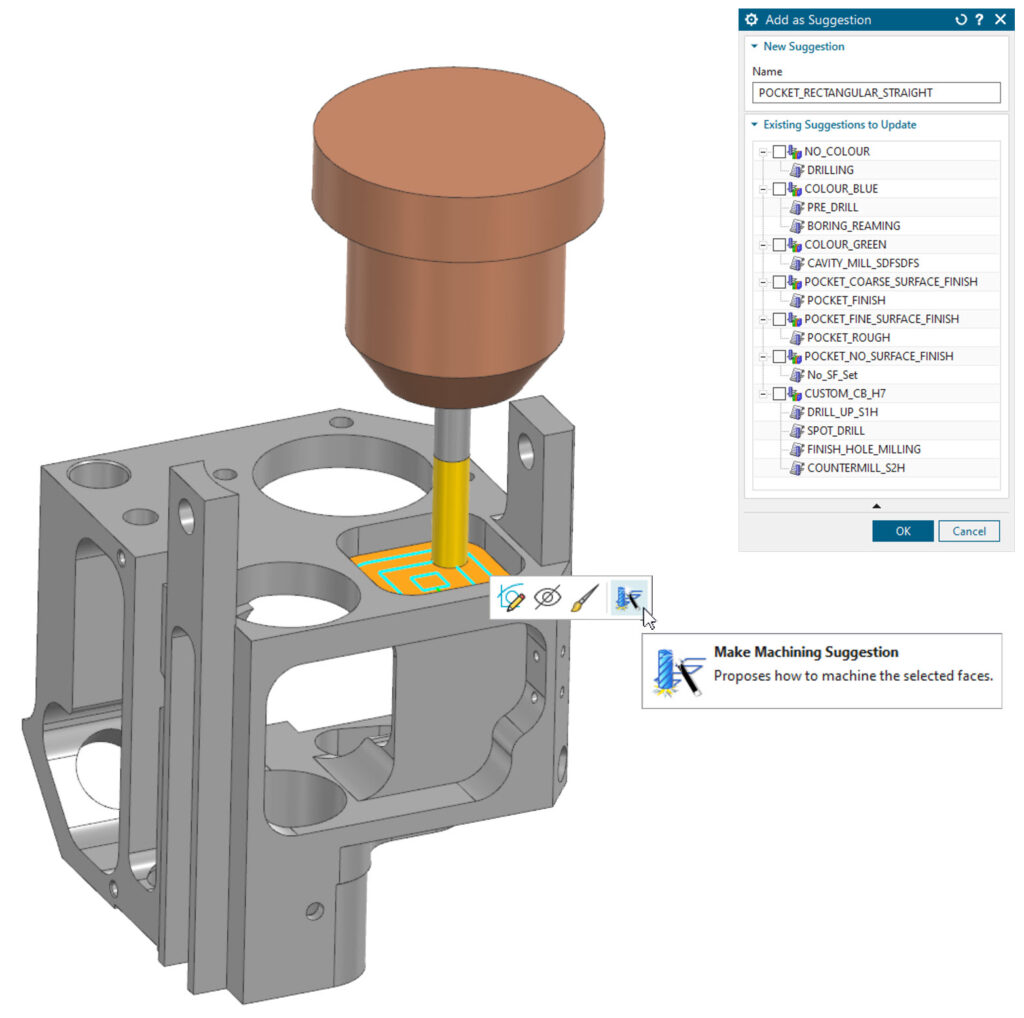

Make Machining Suggestions

Create a complete machining process for a feature with just a click on a component’s face. The latest Make Machining Suggestion feature in NX CAM simplifies toolpath creation, automatically suggesting pre-defined machining processes with an optimized sequence of operations. For example, by selecting the floor face of a pocket you can automatically program the entire pocket using multiple operations and tools.

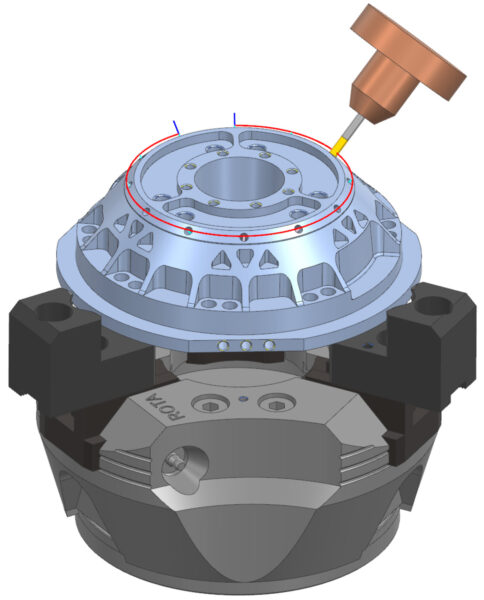

Automatic Hole Machining

Holemaking now includes enhanced automation capabilities. The newly introduced Automatic Holemaking feature allows you to fully utilize the power of Feature-Based Machining (FBM) when programming holes. You can select one or multiple faces with holes and NX automatically detects all holes of various sizes and complexities, groups them, and creates optimized toolpaths to effectively machine them.

Machine Powered Programming

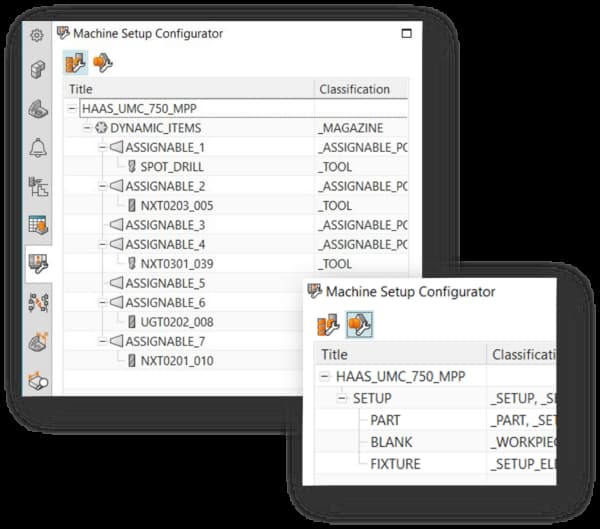

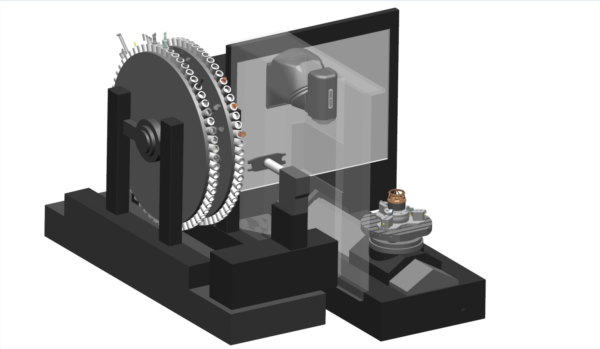

Machine Powered Programming (MPP) integrates machine tool capabilities directly into the programming process. Programmers can use the exact settings and parameters of the selected machine, simplifying the creation of efficient and error-free toolpaths, even for the most challenging multi-axis CNC operations.

The Machine Setup Configurator Navigator transforms commissioning tasks by introducing a dedicated view for part and tool setup.

Machines with specified kinematics in the Machine Tool Builder can now be defined with turrets or magazines featuring static pockets. This enhancement ensures that tools are accurately positioned during CAM programming, improving setup efficiency.

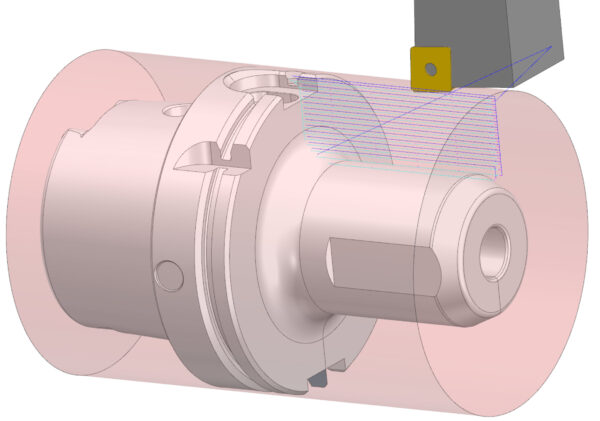

The latest chip breaking option for turning toolpaths provides an efficient solution for managing long, stringy chips during machining. You can now control the tool’s engagement with the workpiece to break chips into smaller, manageable lengths. This improvement enhances chip evacuation, minimizes entanglement, and promotes cleaner machining environments. It also reduces downtime, improves surface finishes, and extends tool life.

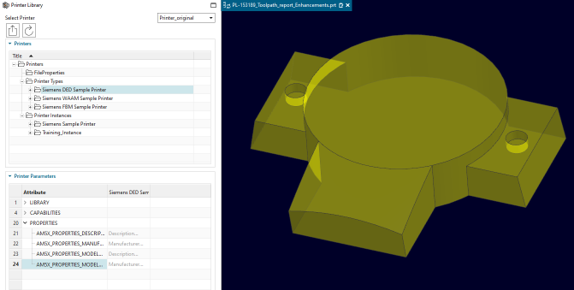

Printer Library

The Printer Library for Multi-Axis Additive Manufacturing allows to create and manage printer families with custom process parameters. It includes Build Styles for Operation Parameters, Build Rules for Custom Process Parameters, and a Material Library to define settings like step-over and slice distance. By assigning specific parameters to output types, such as finish passes or infill strategies, you can enhance control, improve print quality, and streamline additive manufacturing workflows.

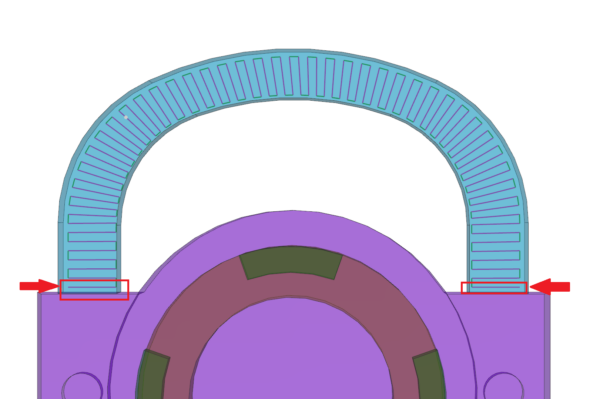

Docking Passes

The new “Mark Docking Passes” feature in NX Additive Manufacturing introduces custom parameters for docking geometry, allowing you to optimize prints where two parts meet. Manage the heat sink effect by applying different process parameters at the docking pass, ensuring higher-quality builds at the contact points. By defining the docking area around selected bodies or faces, you can now reduce energy usage and improve print consistency, particularly in areas where parts touch.

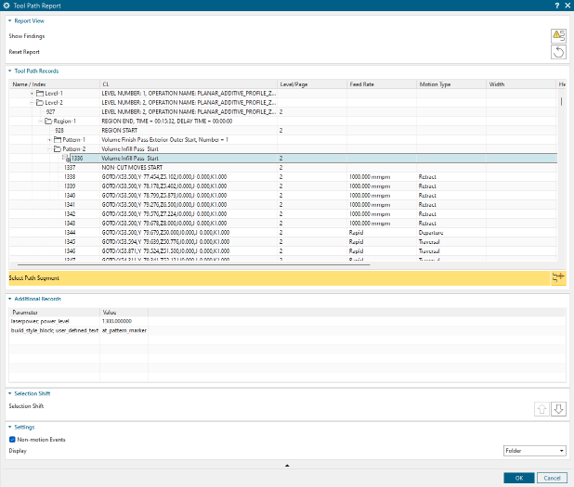

Toolpath Report

Adjust the feed rate for cooling time, to achieve greater control over the cooling process layer by layer. This feature is useful for polymer printers and ensures continuous printing without cooling breaks, preventing part deformation. By adjusting the feed rate based on cooling time, you can increase the time per layer without interrupting extrusion, ensuring efficient and precise printing.

Manifold Checker

The new Manifold Checker feature helps minimize build failures by detecting potential non-watertight bodies and other geometric issues early in the process. You can validate meshes to ensure they are fully watertight and free of intersecting faces, missing surfaces, or gaps—common issues that can lead to build failures. This feature verifies the integrity of 3D models, ensuring they are print-ready before the build process begins.

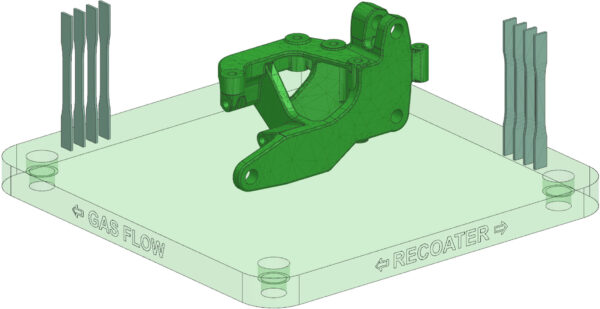

No-build Zones

With the new No Build Zones feature, you can define areas in the build tray where parts cannot be printed, such as regions with sensors or fixturing. These zones are automatically considered during 2D/3D nesting to ensure parts are placed in reliable areas, avoiding interference with machine components. This improves print quality, simplifies post-processing, and enhances build reliability.

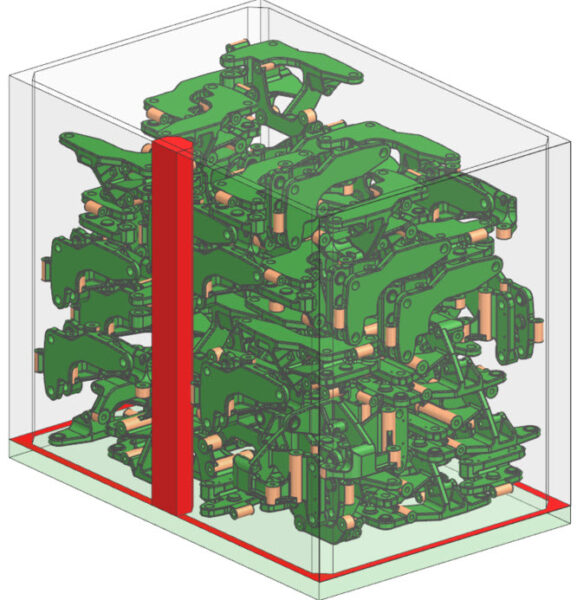

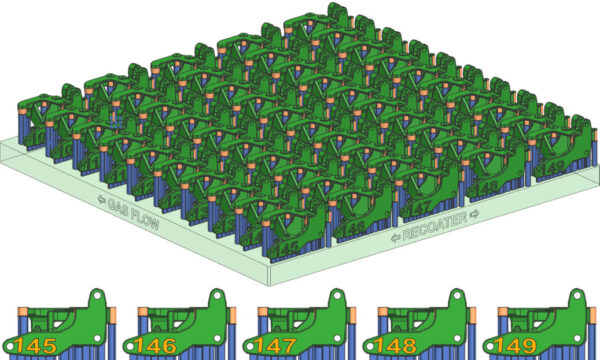

Improved Print Mark Performance

Print Mark Performance is improved, boosting efficiency for parts with print marks across multiple operations, including part addition, patterning, and move/copy actions. With the flexibility to defer print mark creation until output generation, users can reduce overhead, streamline workflows, and improve performance in complex builds, leading to faster operations.

Core design

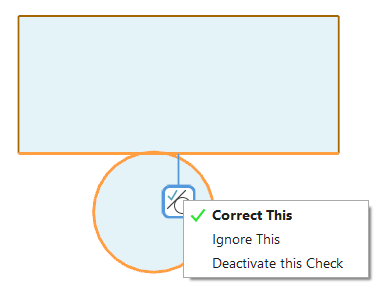

Core Design now includes enhanced Sketch Checking to fix gaps, correct shapes, find small curves, and spot overlapping lines that stop you from finishing a sketch.

Immersive Design

In Immersive Design , you can use the new Sony SRH-S1 headset and its controllers to access Immersive Designer. This tool goes beyond reviewing designs; it lets you create and edit data in real time within a virtual environment.

VAlidation

In Validation, the Checker Editor is designed to ensure that all designs meet specific rules and standards by providing automated, real-time validation. This tool enhances the efficiency and consistency of the design process, ensuring high-quality results with immediate feedback and corrections.

A complete overview of all innovations in NX 2412 is available here:

DO YOU HAVE ANY QUESTIONS ABOUT SIEMENS NX?

![[Translate to English:] Manuel-Obernoeder-AMbitious](/fileadmin/user_upload/ambitious/ansprechpartner/manuel-obernoeder.jpg)

Subscribe to our newsletter to receive the latest news about Siemens NX software.

YOUR PRACTICAL PARTNER

As a Siemens NX AM Expert Partner, AMbitious powered by toolcraft provides training on Siemens NX and can support you with the implementation and use of Siemens NX software together with its modules along the entire AM process chain.